Infrastructure

Manufacturing Facility

Manufacturing is a passion. This person has driven us to set up a world-class manufacturing facility with extreme working efficiencies in record times over the years. We have earned an enviable reputation for flawless project execution and management.

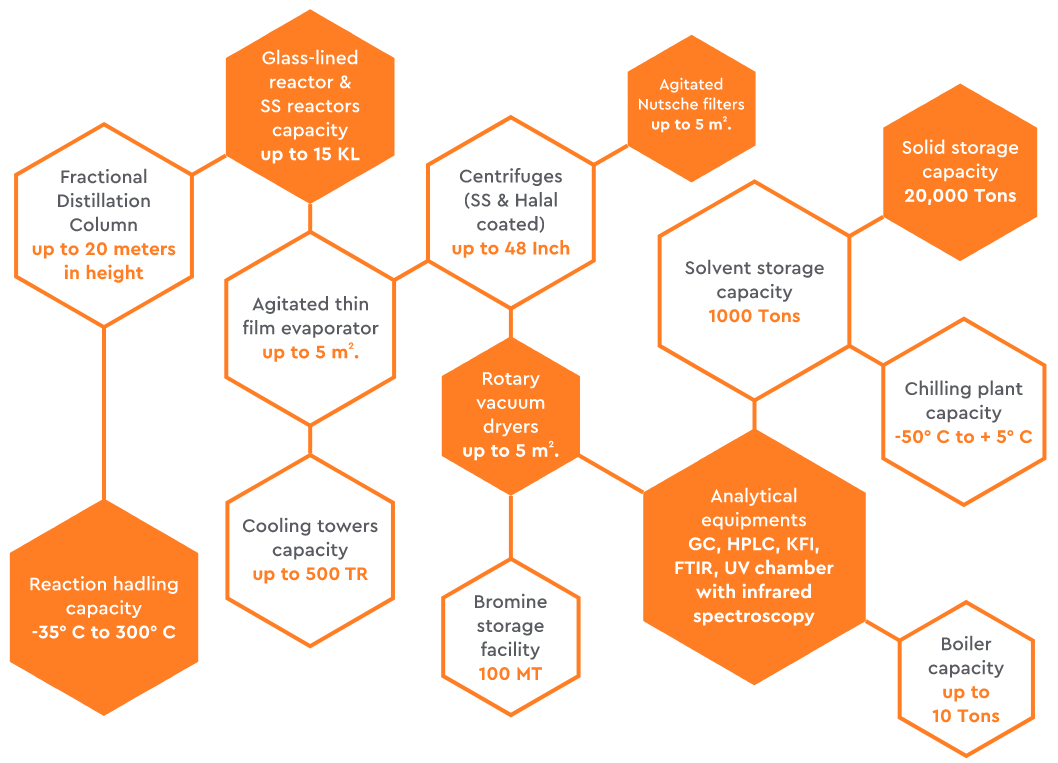

Our site is well capable & maintained with a large variety of reactor sizes ( glass lined, MS and SS reactors ), the material of construction (MOC) with distillation columns( glass lined, MS and SS) and downstream processing including pressure filters dryers, etc. we have adequate utilities for heating, chilling, cooling and vacuum.

At yogi we have world-class process equipment from drier to glass-lined reactors, it has a separate utility equipment section and ETP with a multi-effect evaporator plant, sewage treatment plant, water softening technology and solid waste incinerator.

At Yogi, we have advanced storage facility with a multi-disciplinary racking system. Our facility includes a large solvent storage tank farm & solid storage area. We always use high-quality HDPE Drums, MS Composite Drums, ISO Tanks & IBC Tanks with all necessary quality needs,World-class analytical equipment like gas chromatography, High-performance liquid chromatography, Infrared spectroscopy , Karl Fischer instrument, UV Chamber, Fourier Transform InfraRed (FT-IR) Spectrometer.

- Fractional Distillation Column: up to 20 meters in height

- Glass-lined reactor & SS reactors capacity: up to 15 Kl

- Centrifuges (SS & Halal coated): up to 48 Inch

- Agitated Nutsche filters: up to 5 m2.

- Rotary vacuum dryers: up to 5 m2.

- Agitated thin film evaporator: up to 5 m2.

- Reaction handling capacity: -35 °C to 300 °C

- Chilling plant capacity: -50 °C to + 5 °C

- Cooling towers capacity: up to 500 TR

- Boiler capacity: up to 10 tons

- Bromine storage facility: 100 mt.

- Solvent storage capacity: 1000 tons

- Solid storage capacity: 20,000 tons

- Analytical equipment: GC, HPLC, KFI, FTIR, Uv chamber with infrared spectroscopy