Environment Health And Safety

- Our facility is approved by alcumus ISOQAR and is compliant with the requirements of: ISO 9001: 2015

- Fire hydrant system

- Round the clock ambulance availability

- On-site emergency mock drills

- Periodic health check-ups for all employees.

- Occupational health centre

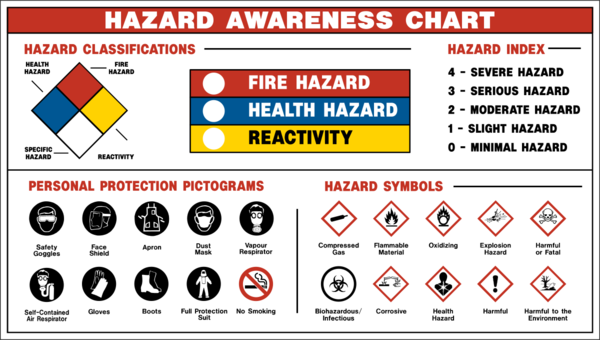

- At our site we have provision of all kind of safety signs and hazard signs

- We have dedicated storage area for hazardous and flammable chemical products.

- Various fire extinguishers spread across our manufacturing unit in order to maintain safety measures.

- We have provided safety helmets, safety gloves, safety glasses and safety shoes to all our front line workers and employees.

- Dedicated safety officers for Production, storage and maintenance purpose.

- Emergency alarm in case of fire or explosion.

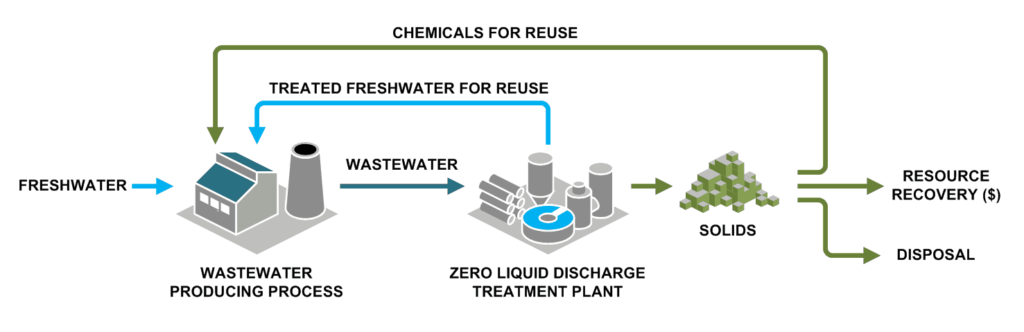

- An effluent treatment plant comprises primary (chemical), secondary (biological) and tertiary (disinfection) treatment facility

- Liquid effluent sent to common effluent treatment plant for further disposal

- Solid/Liquid waste is sent to approved land fill/incineration sites

- Installed a zero liquid discharge system.

1.Developing clean and safe technologies to manufacture quality products by taking steps at the appropriate stages of process devel opment, design, purchase, manufacture, maintenance and packaging.

2.Communicating this policy to all the employees, contractors, visitors and stakeholders. Provide all employees with the necessary

information, instruction, training and supervision needed to ensure equipment quality, safe working practices are adhered to, and

to develop quality, environmental, health and safety awareness amongst employees.

3.Integrating the requirements of environmental protection & sustainable development; minimisation of energy, material usage and

the production of waste; prevention of pollution; Effective and responsible waste management and disposal; elimination/

prevention of occupational health, safety and security to people, asset and environment, safe working conditions and safe behaviour in all our activities.

4.Incorporating appropriate criteria in selection, placement and assignment of personnel, including contractors and other agencies at

appropriate level, empower and make them accountable to achieve QEH&S targets using given facilitates with optimum efficiencies.

5.Encouraging all employee’s active involvement and participation in developing a culture that favours improved processes and control

of preventive aspects also through employee health and safety representatives.

6. Motivating all employees in promoting safe behaviour and healthy habits in the workplace and in everyday life.

Due to the various hazards associated with the production of chemicals, we have installed machinery and equipment to control the discharge of effluents including A zero liquid discharge based effluent plant with high capacity of 50 KLD which includes primary treatment plant, stainless steel evaporator, scrubber sets and filter press and state of art effluent treatment plant equipped with zero liquid discharge solutions including multiple effect evaporator, reverse osmosis for purification of waste and bioreactors for treatment of effluents and removal of organic load.